How to comply with IMO sulphur requirements effectively and cost-efficiently

Everyone is aware of the IMO 2020 Global Sulphur Cap Limit, so the question is: Are you ready to meet the tightened requirements, or are you still considering your options? A scrubber system washes the sulphur out of the exhaust gas, and we have investigated the different types of systems and what things you need to focus on when choosing a scrubber system.

By January 2020, ALL types of ships must limit the level of sulphur in fuel oil to minimum 0,50%*, and shipyards around the globe are busy preparing vessels to meet the tightened regulations.

It is not only a question on how to comply, but it is also a question on how to maintain a safe ship and yet minimise the fuel consumption for powering the scrubbers and how to be prepared for future emission requirements.

But how to comply with the 2020 sulphur requirements?

One way is to use fuel with low sulphur content or alternative fuels. However, compliant fuels are more costly than heavy marine fuel, and it is still uncertain how the prices will develop. The decision depends on factors like the cost of compliant fuels, the CAPEX and the OPEX of a scrubber system, etc.

So far, the industry has favoured the exhaust gas scrubber system which removes sulphur from the exhaust gas which enables a ship to continue operating on the less expensive marine heavy fuel without compromising legislations.

However, there are a lot of things to take into consideration when applying a scrubber system, for example:

- What are the differences between an open loop scrubber, a closed loop scrubber and a hybrid solution, and what should you be aware of before choosing a system?

- Is there sufficient available power, or do you need to optimise the load profile?

- How to make a future-proof investment by upgrading the power management system?

Open loop, closed loop or a hybrid solution?

There are several factors to consider, and this article will highlight some of the things to take into consideration. But let’s start with defining the different options.

- An open loop scrubber system removes SOx and particulate matters from the exhaust gas by utilising seawater as SOx absorbent, and the wastewater is discharged directly into the sea.

- Closed loop scrubbers use chemically controlled sea or freshwater as the scrubbing liquid, which is recirculated and the bleed-off is collected in a storage tank which is emptied in port for appropriate further treatment.

- A hybrid system can operate in either an open or closed loop, offering the advantages of both modes.

When it comes to choosing a scrubber, you need to make sure the scrubber fits the space available. Make sure to partner up with an experienced scrubber manufacturer and have space availability determined before signing an agreement. Often a closed loop scrubber takes up more space and is more expensive to install than an open loop system.

Another thing to consider is your travelling routes. Vessels operating in sandy waters does not comply with an open loop scrubber as the grains of sand can clog the system, leading to increased maintenance cost. Also be aware that some ports have banned open loop scrubbers after January 1, 2020, and more ports are expected to follow.

Maintenance costs for a closed loop system are higher than for an open loop scrubber and remember to take the cost for alkaline water into account. However, the power consumption for an open loop scrubber is higher and will put more pressure on your engines. Then again, a hybrid system will still require higher pump capacity in open loop mode and smaller pumps active in closed mode operation for the filtration system. The installation of both hybrid and open loop systems will affect the energy consumption onboard and may consequently demand modifications to the power management system to ensure power availability and security, control and fuel economy.

Regardless of which system is applied, the quality is crucial. Some of the first scrubbers installed could not stand the acids and therefore have been taken out of operation. Make sure you choose a well-tested system from an experienced supplier.

Do you have enough power available, or do you need to optimise the load profile?

Scrubber makers and technical management will often realise that a scrubber requires additional power and that it consequently will affect fuel consumption. It is essential to ensure you have enough available power onboard.

Ships with a scrubber system onboard require more power to run the scrubber while steaming and it is advisable to optimise the load profile with intelligent load and power management profile in favour of the overall fuel consumption.

If your power system is not tuned for the additional load, blackouts can occur. Having an intelligent power management system with an integrated load management functionality (i.e. DEIF’s consumer management system) will not only prevent blackouts, but it will also improve fuel economy.

How to future-proof your investment?

You can never be 100 % certain that the solution you apply will meet all future requirements. However, there are some things that we believe could prolong the lifetime of your investment.

One thing is to make sure that your system is connectable with a compliance, MRV and energy management/monitoring system such as Blueflow.

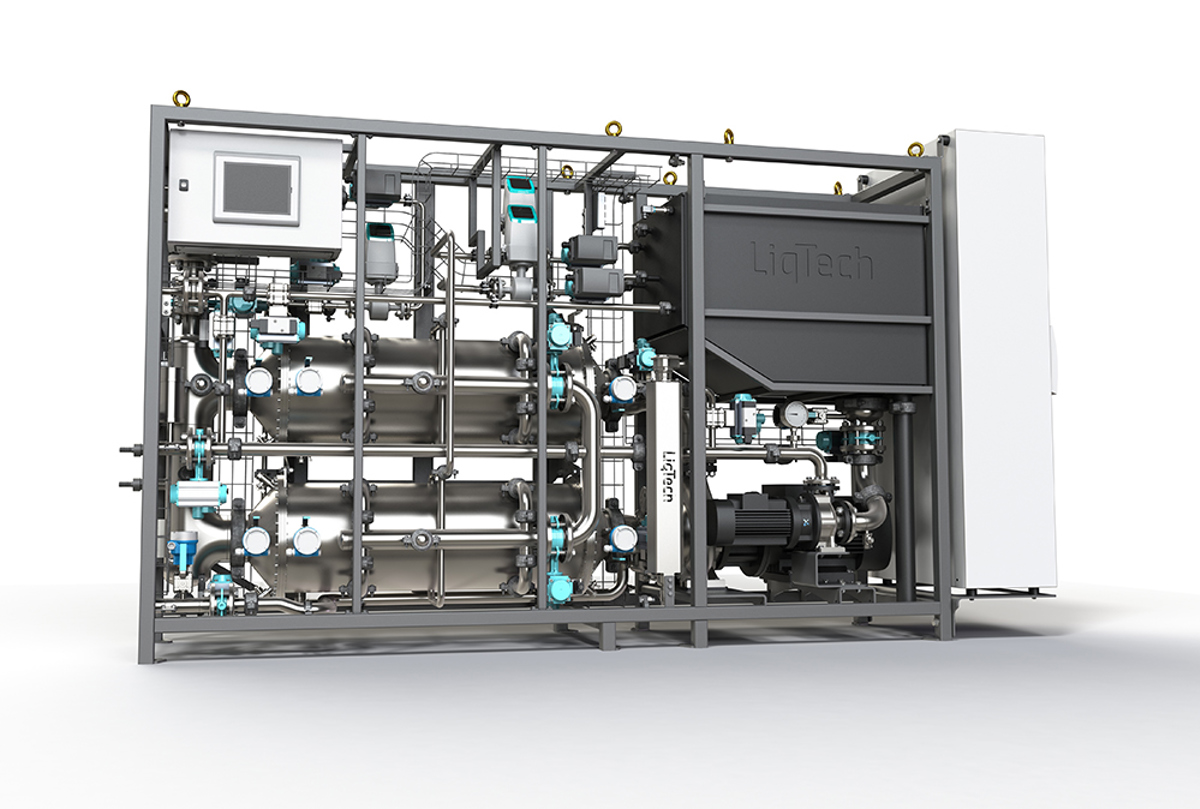

LiqTech

LiqTech is a leader in the development, manufacturing and supply of revolutionary silicon carbide ceramic technology for the purification of liquids and gasses. LiqTech focuses on emerging markets like marine scrubber wastewater, oil and gas filtration, drinking water, mining, heavy metal removal, and finds real-time onboard and remote monitoring beneficial for both compliance verification, filtration uniformity and overall system stability.

Depending on the service agreement, LiqTech offers up to 5-year warranty on continuous use on their filters documenting the level of quality and expertise on filtration of the most aggressive substances in the harshest of environments.

Supplying systems to any size of closed loop and hybrid systems to even the largest vessels, LiqTech has long-term experience in working with top marine scrubber manufacturers.